NEWS

HERE WE GROW AGAIN: CIT EXPANDS TO MEET GROWING DEMAND

We’re excited to announce a major expansion at CIT - another big step forward as we continue to grow and serve our customers with excellence. Our newest addition: a brand-new 75,000 square foot facility!

CELEBRATING COLLIN COYLE: ENGINEERING TALENT ON THE RISE AT CIT

We’re excited to celebrate a big milestone for one of our own - Collin Coyle, Design Engineer at CIT, has officially graduated from Sinclair College with his Associate’s Degree in Mechanical Engineering!

CIT’S AEROSPACE JOURNEY: RAPID PROGRESS FUELED BY PRECISION AND INNOVATION

Over the past five years, Contract Industrial Tooling (CIT) has made tremendous strides in the aerospace sector. From our early projects to securing large-scale government contracts, our growth has been fueled by a deep commitment to precision and innovation.

JOSH SEMBACH ON AEROSPACE DESIGN

As CIT’s aerospace business rapidly grows, we caught up with Josh Sembach, Lead Design Engineer for aerospace, to learn more about what’s happening.

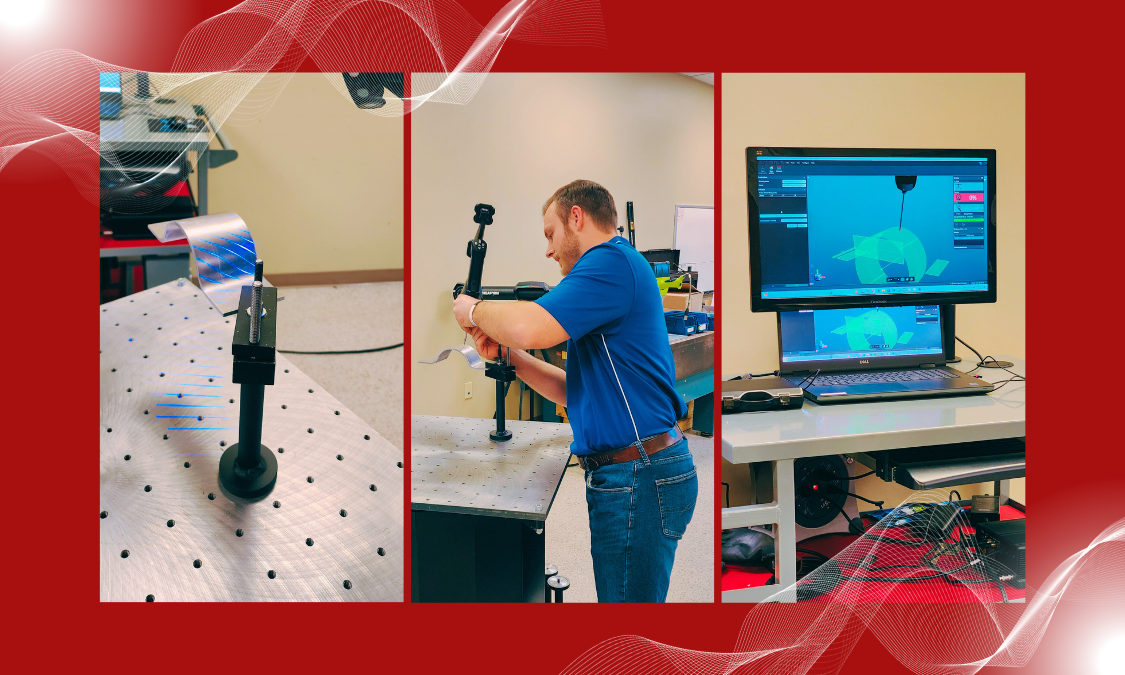

QUALITY TEAM ADDS 3D SCANNING CAPABILITY

As our Quality team crafts our path forward to provide the latest technology to our clients. We’ve added 3D scanning capabilities to provide real-time, accurate feedback to the production floor. This cannot be done using traditional equipment and save significant time. Check out this interview with Reed Bolser, quality technician.

CIT NAMED WAYNE COUNTY AREA CHAMBER OF COMMERCE CORPORATION OF THE YEAR

Adapting, innovating, and producing materials crucial for society in some of the most trying times our nation has ever faced; the Contract Industrial Tooling team rose to the occasion and found a way to be part of the solution. CIT is proud to be the Wayne County Area Chamber of Commerce’s 2020 Corporation of the Year Award recipient.

ACQUIRING CLIENTS AND BUILDING RELATIONSHIPS AT CIT

Quality focused. Client driven. These are the words that CIT Inc. lives by. As the one stop shop for all manufacturing needs, CIT is dedicated to giving their clients the best. After all, without their clients, CIT wouldn’t exist.

WHO IS CIT? THE PRESENT AND THE FUTURE OF CIT MANUFACTURING

CIT Inc. is more than just the rapid response hospital beds that they’ve produced. Though this recent product has received a lot of attention, CIT is dedicated to so much more.

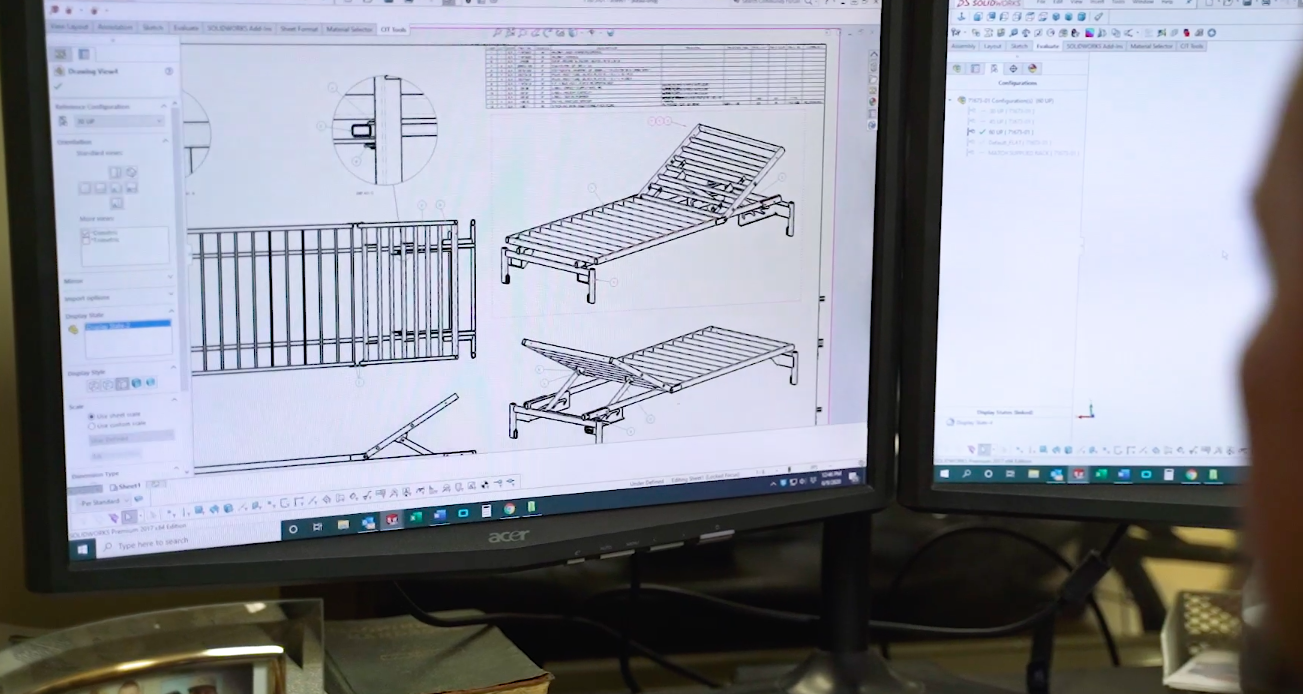

FROM CONCEPT TO MANUFACTURING: HOW THE BEDS WERE MADE

CIT Inc. took an idea, adapted an idea and manufactured that idea in two weeks. They didn’t even have a design when they began.

THE CHALLENGES OF RAPID PRODUCT DEVELOPMENT

When the COVID health crisis caused a shortage of hospital beds, CIT had to manufacture and produce new portable, versatile beds – and they had to do it fast. A 12-week process became a 2-week process.

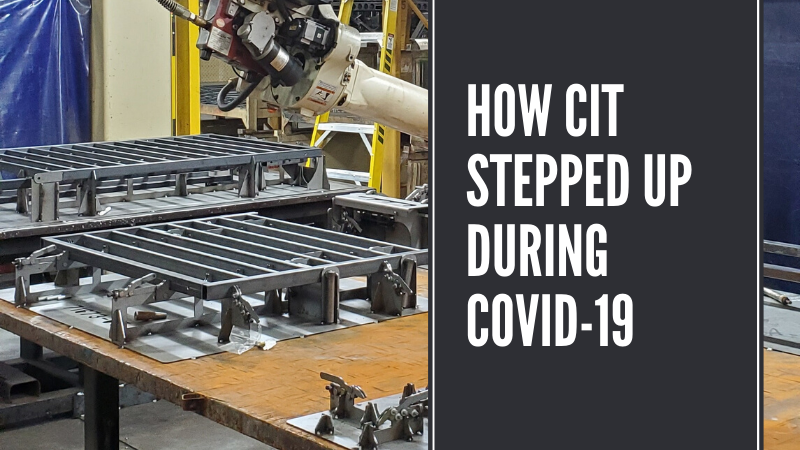

A TEAM THAT NEVER STOPS WORKING: MANUFACTURING RAPID RESPONSE HOSPITAL BEDS

When CIT Inc. quickly went to work to make life-changing rapid response hospital beds to help in the COVID-19 crisis, they had a special weapon – a team. Though CIT had the tools, skills and experience needed to get the job done, their work ethic and teamwork is what made this project so successful.

CIT Stepped Up to Help Save Lives in the Coronavirus Crisis

When coronavirus swept the nation, no one was truly prepared for the damage it would cause. As it spread, some lived in sickness while others lived in fear. Meanwhile, healthcare heroes worked endless hours to do all they could. So, when the healthcare workers needed help, CIT Inc. was there.

Richmond, Indiana Manufacturer, CIT, Produces “Rapid-Response” Hospital Beds to Help Reduce COVID-19 Shortages

As coronavirus (COVID-19) rapidly spreads throughout the United States, it is causing a shortage of hospital beds impacting the delivery of healthcare services in places like New York. This has highlighted the critical need to ensure plenty of capacity for COVID-19 intensive care patients. With a shortage of beds, a portable, rapid-response bed was needed to shore up shortages in health care facilities during a crisis like COVID-19.

MYSTIC SEAPORT TESTIMONIAL AND CIT FEATURED ON MCFA

Recently, a CIT built cab was featured on the MCFA website and in Mystic Seaport’s video entitled “Mystic Seaport’s Long History with Lift Trucks.” Check out the video below to see a CIT cab in action.

3 KEY ELEMENTS IN CIT’S QUALITY STRATEGY

CIT has proven to be successful in creating the highest quality products for clients over the last 30 years. How do they do it? With a quality strategy that meets ISO requirements and puts clients first, as well as by implementing quality control strategies throughout the entire manufacturing process. These are the three key elements in CIT’s quality strategy.

CIT ENTERS OUTSOURCED AEROSPACE TOOLING MARKET

Whether it’s off-loading or outsourcing, there is an opportunity for outsourced tooling in the aerospace industry. OEMs are farming out a variety of tooling work. This opportunity comes with expectations, processes and standards that are beyond any industry CIT has ever worked with, requiring the utmost design, quality and expertise.

WHY CIT BUILDS ROBOTS

When there’s a need in the market, CIT looks to meet it. There was a noticeable lack in the robotics market and instead of sitting by and letting someone else handle it, CEO Kim Wuertemberger decided his team would solve the problem and start creating robots of their own. CIT builds robots for several reasons: cost, custom application, efficiency for the client and offered flexibility.

WHY THE MITSUBISHI CATERPILLAR CAB MATTERS

In case you missed it, CIT recently featured the cab that it produces for Mitsubishi at the CONEXPO Show.